STAND-ALONE DEHUMIDIFIER

DRY-O-MENT

DRY-O-MENT

STAND-ALONE DEHUMIDIFIER

Standard system supply for all units 415 VAC, 3 Ph+N+G, 50 Hz. Optional choice of other system supply can be 200V, 380V, 400V, 440v, and 500v, 3 Ph, 50 or 60 Hz, AC. Standard choice of desiccant regeneration is Electric with options Steam, Gas, Hot oil, water or a combination thereof.

- Available in size from 100 CMH to 50,000 CMH

- Standard products include fully functional units with necessary safeties and electric relay based controls or optional PLC based Controller.

- Desiccant rotor technology removes water directly from the air.

- Designed for industrial processes, including low dew point applications.

- Available with integrated pre and post cooling systems

- Fast, simple access to all electrical and mechanical components through hinged doors or removable access panels

- Desiccant cassette can be removed for cleaning to extend rotor life and efficiency

- Choice of Gas, Steam, and Electric Reactivation

- Standard features include easy access inlet filters, self-adjusting/tensioning rotor drive components, and easy seal adjustment.

- Robust industrial duty structural frame and panel design

- Highly compact design - lowest footprint area.

- Fully factory assembled, reduced installation time on site and lower costs.

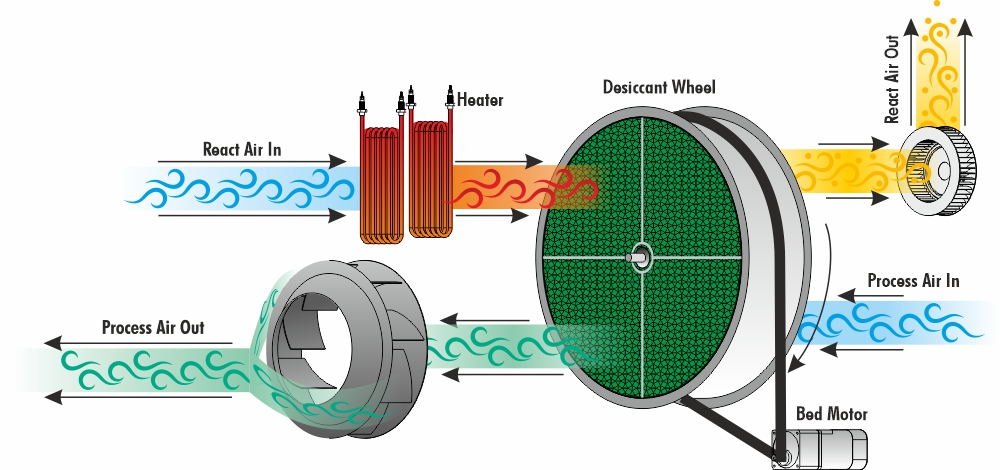

- REHOBOTH dehumidifiers operate on the principle of adsorption of water vapor from the air. The desiccant used is silica gel, which is formed on an inorganic substance.

- The desiccant and substrate are arranged in a wheel-shaped rotor matrix having thousands of small parallel air passages extending through its thickness.

- The desiccant rotor is housed in a cabinet that is separated into process and reactivation sections. In the process section, moist air passes through the rotor, and the silica gel adsorbs the moisture.

- To drive the absorbed moisture out of the desiccant, the rotor slowly rotates into the reactivation section, where a second heated air stream passes through the rotor. The hot air heats the desiccant, driving the water out of it. The moisture-laden reactivation air is usually exhausted outside. The reactivated desiccant rotor rotates back into the process section to provide continuous drying of the process air.

- In many applications, the process air is cooled before entering the desiccant rotor to enable the system to produce dry air.

- The reactivation air stream may be heated by electrical heaters or any other source of heat depending on the application and available utilities.

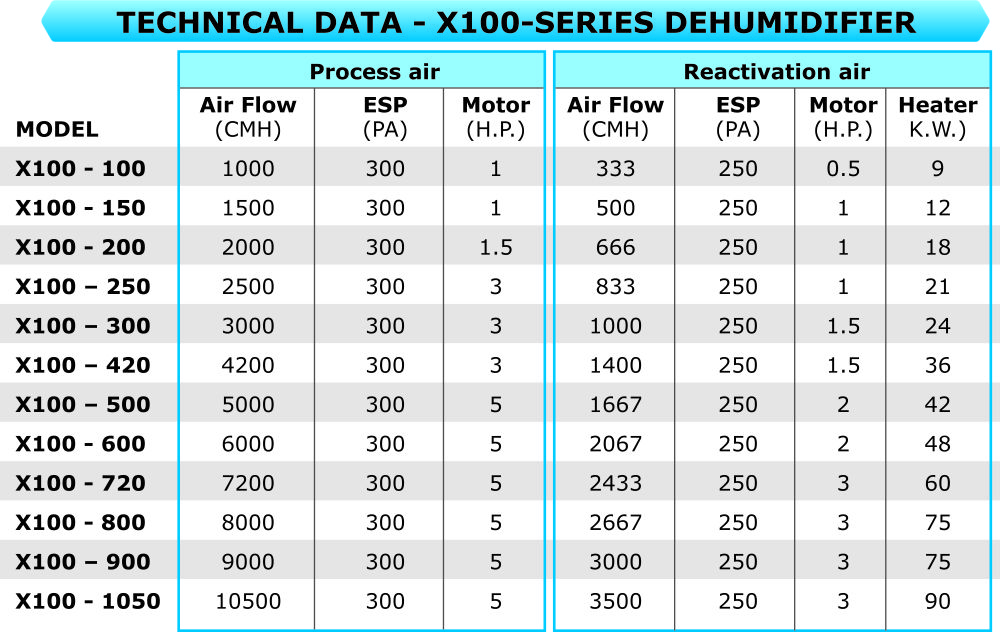

- Available in 13 models, 100-10000 CMH supply air, 4kg/hr to 64 kg/hr moisture removal

- Utilize highly efficient solid desiccant fluted wheel

- Maximized dehumidified air flow capacities with very high and consistent performance levels.

- PLC or electric relay based control choice

- G4 grade filters on both air streams

- Robust industrial duty structural frame and panel design

- Highly compact design - lowest footprint area

- Fully factory assembled, reduced installation time on site and costs

- Uprated supply air flow capacity or higher available static pressure

- Supply fan with frequency control

- Stainless steel sheet metal casing (optional)

OUR OTHER PRODUCTS

The perfect climate for your application

TRAY DRYER

WITH DEHUMIDIFIERS

HUMIDIFIER

TRAY DRYER

WITH DEHUMIDIFIERS

HUMIDIFIER

INDUSTRIES WE SERVE

The Spectrum of Industries We Cater toSome of our valuable clients

Get in touch

Initiate a Connection with Us

Contact Us

We Await Your Interaction

Kindly complete the form below, our team will promptly reach out to you.

Copyright © Rehoboth Enviro Systems. All Rights Reserved.